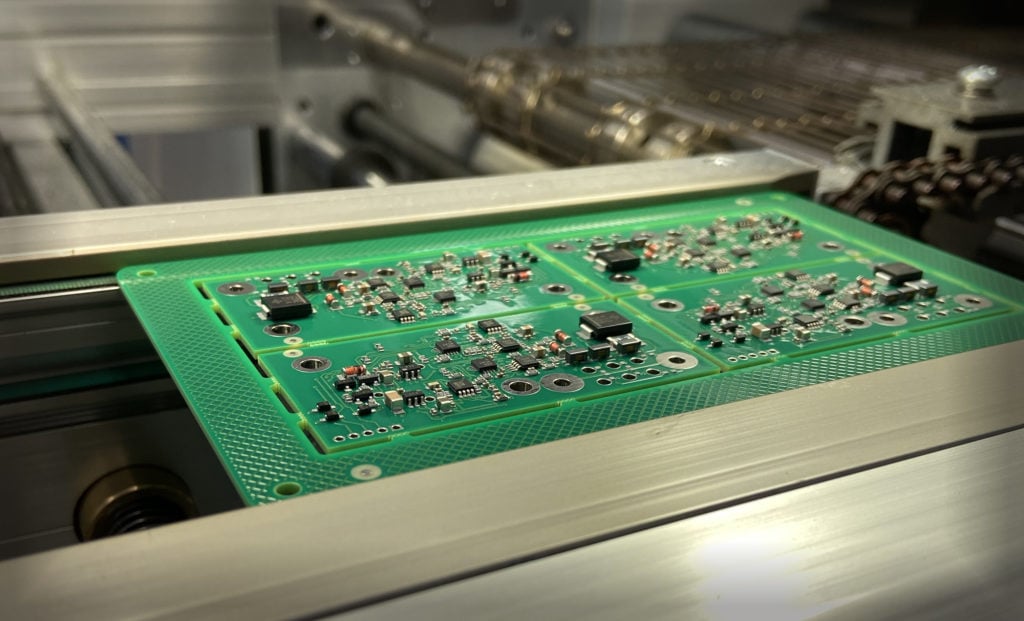

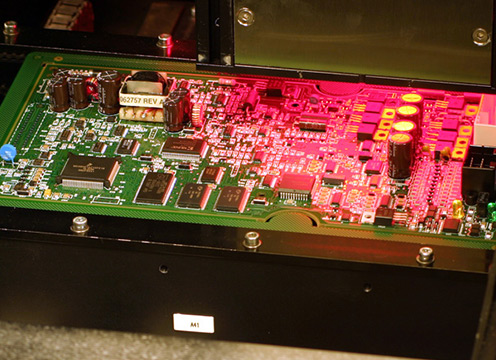

Our staff of surface mount technicians is committed to producing quality products, utilizing the latest , most efficient SMT technology available in the industry.

Quality is never compromised at the expense of speed, all while placing over 80,000 parts per hour amongst 4 high speed SMT lines.

Not only do our SMT lines build your products quickly and efficiently, but they also make simple work of processes other contract manufacturers may deem challenging, such as:

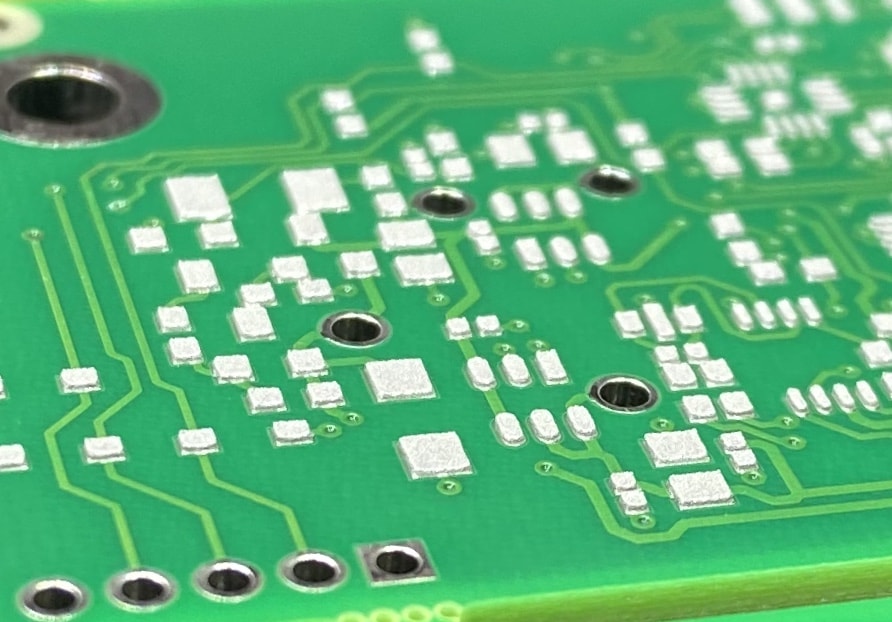

- Placing fine pitch components

- POP (Part on Part) Assembly

- The placement of component sizes from 0201 up to a max size of 74mm square, with accuracies to +/- .025 mm.

- Accurately placing BGAs and micro BGAs using the high-resolution grayscale vision processing system.

We offer leaded, as well as lead free (RoHS) assembly options for all SMT builds.

POST ASSEMBLY REFLOW:

After assembly, the boards are cured via our reflow ovens through a total forced convection process. This allows greater equilibrium to reflow and reduces the likelihood of overheating, which can thermally stress the components and printed circuit boards. Temperature gradients across boards packed with both large and small components are minimized as a result.