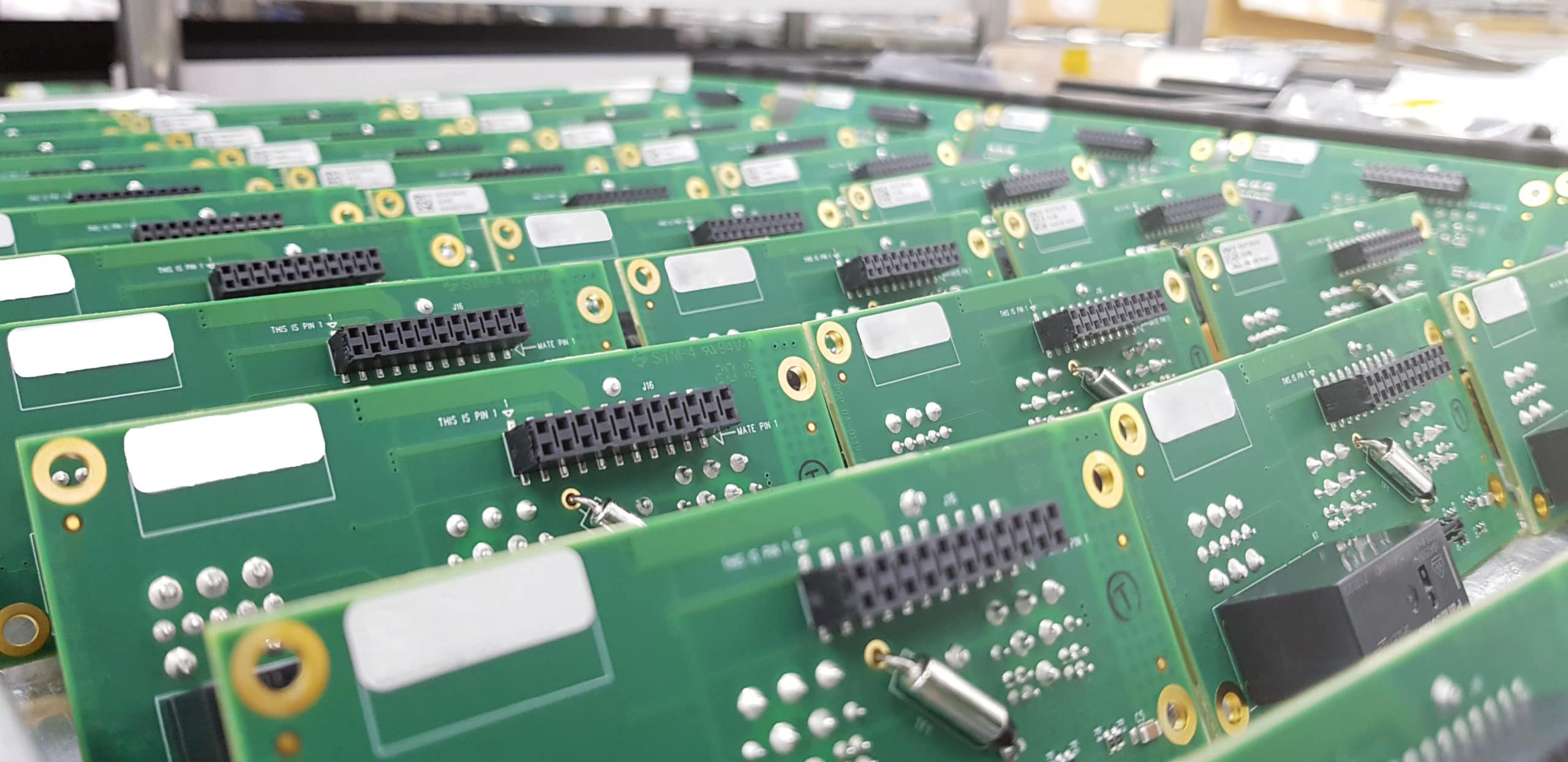

Complete thru-hole assembly technology, with an emphasis on quality and detail

For printed circuit board assemblies requiring thru-hole technology, we offer complete manufacturing solutions. Component prep, load, and hand soldering are performed using a variety of methods.

Wave Solder Technology

Wave soldering is done using our Vectra wave soldering systems and flux residue is removed with an H20 inline cleaning system utilizing de-ionized water. Our high performance dual wave technology allows for defect-free soldering of conventional thru-hole assemblies.

Selective Solder Technology

For densely populated mixed technology assemblies that require both SMT and thru-hole assembly, Circuit Pak offers selective solder capabilities. This technology allows us to efficiently process densely populated mixed technology assemblies with ease.

We offer both Tin/Lead and Lead Free (ROHS) solder options for wave and selective solder processes.