Value-added services that set us apart from the competition and put the final touch on your assemblies

In addition to our PCB assembly services, we also offer an extensive list of additional services to meet your needs and further enhance your assembly.

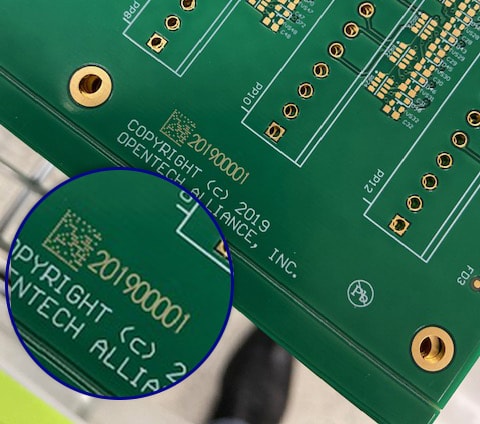

PCB Laser Marking

PCB laser marking/serialization is necessary for inventory control and tracking. Many conventional methods such as labels, however, are time consuming and require additional consumables and you run the risk of the labels eventually coming off, once the assembly is introduced to various elements in the field.

Our fully automated FlexLink F5000H PCB laser etching system overcomes these challenges. For one, it makes no direct contact with the circuits, substrate and other sensitive components. It engraves a permanent marking on the PCB, that will ensure your serial number/marking will be there for the life of the PCBA.

We offer many options for engraving such as 2D barcoding and text.

In-Circuit Testing (ICT)

We offer 2 HP3070 ICTs that allow for more in depth testing of your finished PCBAs. This test utilizes a bed-of-nails test fixture to access multiple test points on the PCB’s bottom side. Through these access points, the ICT can then transmit test signals into and out of PCBs at high speeds to perform thorough evaluation of components and circuits.

ICT checks and detects shorts , opens, missing components, wrong value components, incorrect polarities, defective components and any current leakages that might exist in regards to circuitry. It does all of this in less than 1 minute typically!

A customized fixture is required for each PCBA and is typically costly and recommended for mature products that are in the high volume production stage and is excellent at detecting parametric failures, design related faults and component failures.

Conformal Coating

For PCBAs that need to weather the elements, we offer conformal coating services as well in order to help protect the electronic components from the environmental factors they are exposed to. This process will dramatically increase the durability of your assemblies in the field, while having minimal effect on the total weight of the product.

To learn more or inquire about this service please contact us to discuss your upcoming build(s).