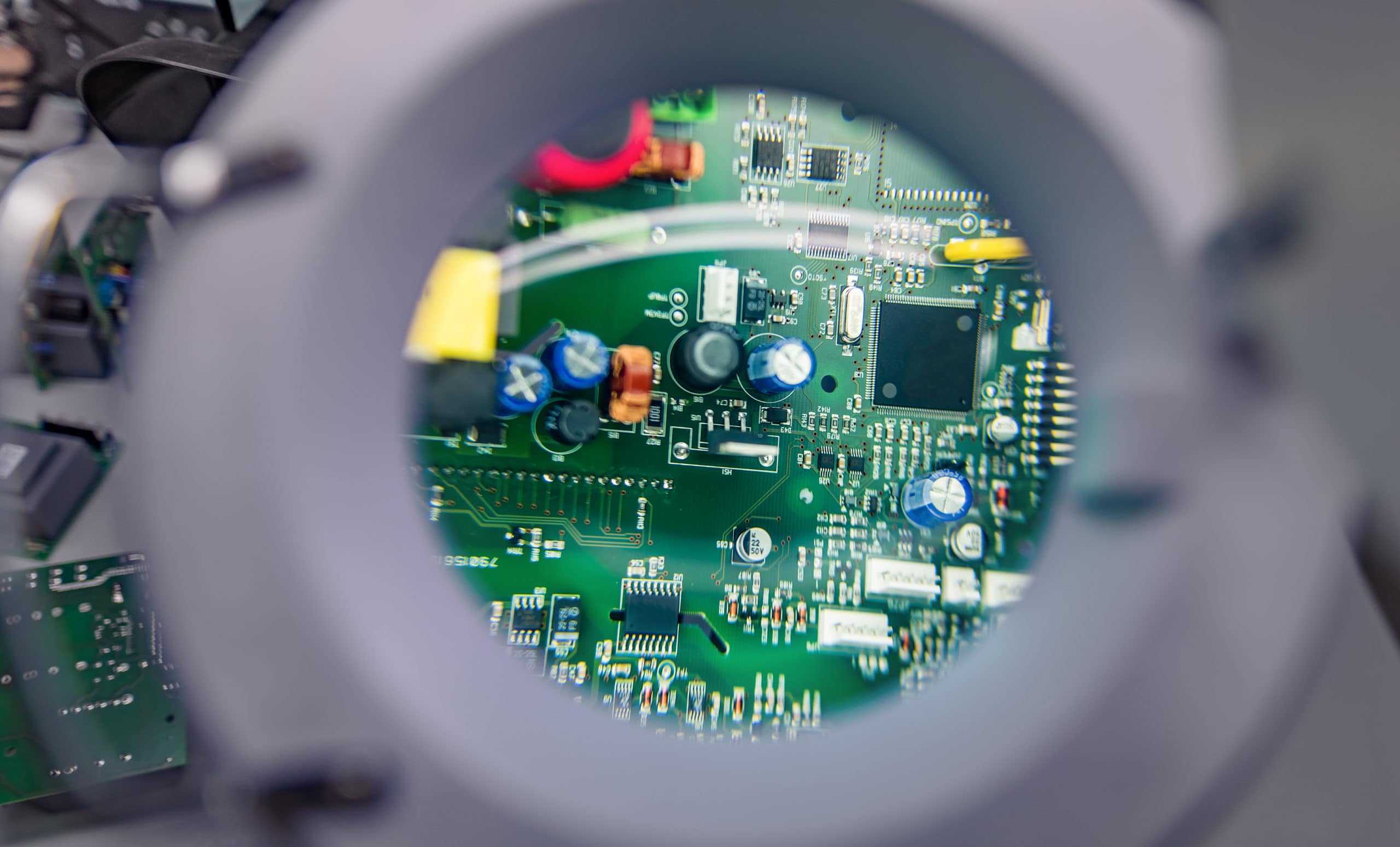

Circuit Pak’s quality control department combines state-of-the-art defect-detection equipment with skilled technicians that have an average of 20+ years of experience!

Quality control for us is something that happens at each and every step along the production path. Numerous checks and balances are put into place to ensure that once your completed assembly leaves our facility, you can be confident you are receiving a product built to the highest standards.

Manual Inspection

Every PCB goes through a 3 stage, rigid visual inspection process that adheres to IPC-610 Class 3 standards. In addition, we also have the capability to run your PCB through our Automated Optical Inspection (AOI) systems.

Automated Inspection

These AOI systems rely on state-of-the-art technology for printed circuit board inspection that can either replace, or compliment, manual visual inspection. By utilizing the AOI systems you take the human factor out of the equation, and are assured a consistent , thorough inspection every time. In addition, the AOI systems offer full defect coverage at the highest throughput. By combining multiple cameras and camera angles assemblies can be inspected for placement, solder joint quality and a variety of other defects, resulting in a typical cycle gain of 80%.